What is Freeze-Drying or Lyophilisation and its Applications?

Freeze drying or Lyophilisation is a process that is used to dry or preserve perishable material (food or tissues or blood plasma or anything, even flowers), without destroying their physical structure. This process extracts the water from food and other substances so that they remain stable and can be stored at room temperature for a long time.

Freeze-drying is carried out by a process called sublimation. In this process the material that needs to be freeze-dried is first frozen to a particular temperature so that the water content in the material becomes ice and then the temperature increased and pressure reduced in near perfect vacuum so that the ice sublimes into water vapour without actually melting the material. This water vapour is collected in a condenser where it condenses into ice.

Freeze drying is also known as cryodesiccation or lyophilisation. The main objective of freeze-drying is, that the product should be well soluble in water and should have the same characteristics of the initial material.

Lyophilise is derived from the Greek "made solvent-loving”

Explanation of terms used:

Sublimation – Transition of a substance from solid to vapour state without passing through an intermediate phase called liquid phase.

Triple Point – Triple point is the lowest temperature at which the solid and liquid phases of a material can coexist.

Fact to remember:

Temperature and pressure are two major factors that determine the phase in which a substance can exist. For every substance to exist in a particular phase, the temperature and pressure have to be in the agreed range, without which that phase cannot exist.

For example, for ice to exist, it needs a particular temperature and pressure, without which it may become either water or water vapour.

History or origin of Freeze-drying:

The freeze drying process has been known to man many years before, but was developed and actively used during the World War II when U.S had to send Serum to Europe for the purpose of medical treatments. Refrigeration of the serum was required, but the facility was not available as required and hence the serum got spoiled before it actually reached the recipients. To overcome this issue, they started using the freeze-drying process to freeze dry the serum, after which it was chemically stable and viable. It did not require refrigeration.

The success of this process lead to this technique being applied to penicillin and this has now become a very important technique to preserve biological materials. Some of the field in which this technique is applied are, pharmaceuticals, food processing, restoring water damaged documents, chemical industries for hydrocarbon analysis, ceramics manufacturing, and many more.

The freeze-drying process:

The freeze drying process itself consists of four major stages or steps. They are the pre-treatment stage, the freezing stage, the primary drying stage and the secondary drying stage.

What is Freeze Drying?

Pre-treatment stage:

The pre-treatment stage includes any treatments to materials before they are actually frozen. Treatments can be done for various purposes and different materials will need different treatments depending on what the material will be used for and depending on its own properties. Sometimes pre-treatment is carried on to make the material meet the needs of the freeze-drying process, for example, to improve the ability of the material to withstand the freeze drying process and time and to improve the quality of the finished product.

Pre-treatment can be applied to achieve any of the following:

- To increase the surface area of the substance in order to make drying quicker

- To improve the stability of the material by adding certain elements or ingredients

- To improve the way in which the substance is processed by adding certain ingredients

- To increase the concentration of the substance or its product

- To reduce the amount of solvents that have high vapour pressure.

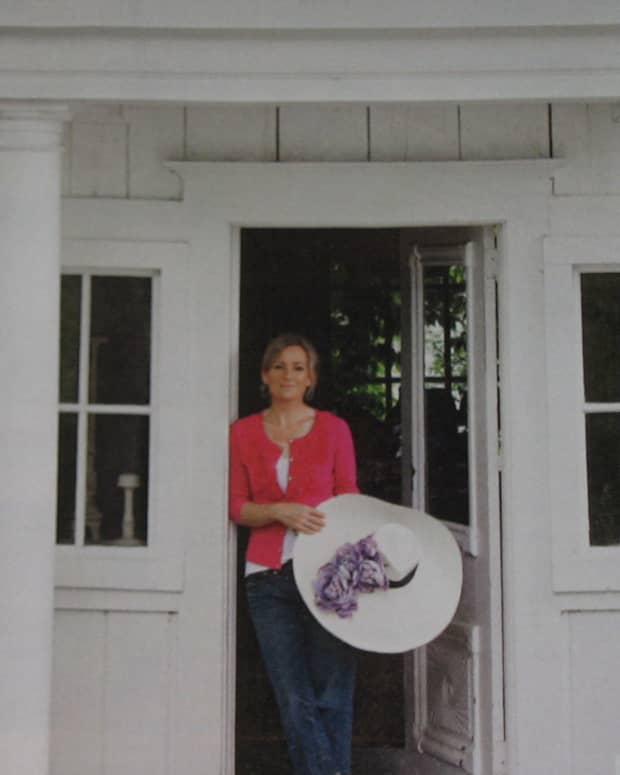

- In case of flowers, it helps to maintain the colour, soften the petals and to prevent it from shattering. Antioxidants maybe added to prevent the petals from browning and colour setting agents are added to reduce fading.

Some of the pre-treatment methods or processes are:

- Freeze concentration, a method that is used to remove water from the substance by freezing it.

- To maintain a balance and keep check on the solution phase concentration

- Pre-treating to preserve the appearance of the product like colour and freshness and to prevent shrinking

- If there are any reactive or chemically and biologically active components, they are then pre-treated to stabilise the products

- Pre-treatment can be done to increase the surface area of the material / substance

- To reduce the amount of high vapour pressure solvents.

Freezing stage:

This is a very important stage because, if the freezing is not well done it can ruin or spoil the material. Freeze drying process can vary depending on purpose and quantity of material that need freeze drying. In laboratories, for freeze drying specimen or small quantities of any material, a freeze drying flask is used. The material to be freeze-dried is placed in a freeze-drying flask and this flask is rotated in a bath containing dry ice and methanol or liquid nitrogen. This is called a shell freezer.

For large scale freeze drying, the freezing is done in a freeze drying machine. The material has to be cooled below the triple point so that sublimation takes place in the further stages ahead without melting the material.

The freezing temperatures are between -50 oC and -80 oC and this is very important because if not properly done, will spoil the material during drying process.

Primary drying stage:

Once the material is frozen under the required conditions, it is put through the drying process where the frozen solvent in the product is vapourised. The pressure is lowered (few millibars) in the chamber where the material is kept by applying partial vacuum and the temperature is increased just enough for the ice to sublime. The heat has to be gradually applied and hence this process can take a few to several days depending on the material and quantity of material freeze-dried. Almost 95% of the water content in the material is dried in the primary drying process and vacuum speeds up the sublimation process. There is a condenser chamber for the water vapour to condense and solidify into ice so that it does not go back to the vacuum pump and affect its performance. Condenser temperatures are usually below -50 oC.

Note: At low pressures like this, heat is generated by conduction or radiation and the convection effect is negligible.

Secondary drying stage:

This drying stage is often called desorption and is to remove any water molecules that are left absorbed in the substance after the previous drying process. The primary drying process vapourises only the frozen water molecules. The temperature of the chamber is increased more than the primary drying stage (maybe even above 0 oC). The pressure is lowered a bit more depending on the material freeze-dried. The process that takes place here is diffusion. Once all the water is vapourised and the freeze-drying process is complete, the vacuum is broken by an inert gas like nitrogen and then the freeze-dried material is sealed. There may be 1% to 4% residual water content in the finished product.

For better stability and longer storage, the final freeze-dried product should have less than 3% of the original moisture content and should be properly sealed airtight.

Properties of freeze-dried products:

- Freeze dried materials if sealed airtight can be stored at room temperature without refrigeration and preserved for many years as reduced water inhibits action of microorganisms and enzymes.

- The originality of the substance is maintained unlike dehydration.

- Freeze-dried materials do not shrink or toughen

- The smell, flavour, nutrition of the freeze dried materials remain unchanged.

- Freeze dried products can be rehydrated quickly and easily because microscopic pores are generated during the freeze drying process in places where ice crystals sublimated.

- A product that has been freeze dried to below 3% of its original moisture content, if exposed to an environment that has more moisture content than it has, will absorb as much moisture as it can and degrade.

Types of Freeze dryers:

There are basically three types of freeze dryers, but all of them have the vacuum pump (used to reduce the pressure in the chamber where the substance is placed) and the condenser (removes moisture by condensation) in common.

- Manifold freeze-dryer: A short circular tube is used to connect multiple containers with the dried product to the condenser. These are usually used in laboratories where liquid substances need to be freeze dried in small containers. This is also used on products that need to be preserved for a short period of time. This dryer has only the primary drying process and a heater needs to be attached to achieve the secondary drying process. The primary drying process freeze-dries the product to have less than 5% moisture content.

- Rotary Freeze-dryer: Has a single large cylindrical chamber or reservoir for the dried substance. This chamber is rotated to achieve uniform drying throughout the substance. Used for drying pellets, cubes and other pourable substances.

- Tray style freeze-dryer: Has a single large chamber or reservoir for the dried substance which is usually rectangular in shape. There are shelves on which products to be dried are kept. It is used to freeze dry a variety of materials like pharmaceutical solutions, tissue extracts that can be place in trays, vials and other containers. Products can be freeze-dried in bulk too. This has both the primary and secondary drying process and produces the driest products that can be preserved for a long time.

Applications of freeze-drying:

Pharmaceuticals and biotechnology: Freeze drying plays a very important role in the field of pharmaceuticals and biotechnology. Most vaccines and injections have a very small shelf life and this can be improved by freeze-drying them. It will then be easier for shipping and also for storage. Tablets are also produced using the freeze-drying method as this method increases shelf life and stops degradation of the product.

Since the freeze drying process does not shrink the product but leaves pores in places where there were moisture content, makes it a perfect method of preservation while reinstating the process.

Food industry: Freeze-drying finds extensive use in food industry. In food industries, these freeze-drying machines are used to preserve food. The final freeze dried product is light weight. An important and very interesting example of freeze-dried food is the preparation of freeze dried ice-creams which is also called astronaut food.

Freeze dry methods are also used to produce essences and flavours for food. Hikers who walk for long distances often tend to use freeze dried food as they are light weight to carry and are long-life compared to other food. They are reinstated when water is available.

Some Instant coffees are also freeze dried and they can be quite expensive, compared to other coffees.

Freeze dried fruits are eaten as healthy snacks or with cereals for breakfast. Some herbs that are used in the cuisine are also freeze dried.

Technology: The freeze-drying process also finds extensive use in the chemical, biological and medical technologies. Elements that are used in a chemical reaction are sometimes freeze-dried to make them more stable and to help them dissolve easily in the solvent.

Freeze-drying is also used in bioseparation processes where different components of a material are separated. It is also used to increase the concentration of substance that have very low molecular weight.

Other Uses of freeze-drying:

There are various other uses for freeze-drying. Some of them are:

- To recover water damaged books and documents and in this particular process, the restoration quality depends on the original material with which the document was created.

- Used to preserve special strains of microorganisms in bacteriology

- Used in ceramic processes where softer particles with similar chemical compositions are created

- Used in floral preservation, for example preserving wedding bouquets and also to create freeze dried biological samples that are used in floristry

- To stabilise chemicals that are unstable, reactive, temperature sensitive and biologically and chemically active in their liquid form and to give them a longer shelf life.

- Used to improve the solubility features of certain substances.

- Used to process lactic bacteria as these can be easily affected by heat.

- Used to preserve archaeological specimens

- Used to preserve tissues that will be used in surgery

- Specimens in museum like plants and animals and other vegetation for research are preserved by freeze-drying

Advantages and disadvantages of freeze drying:

There are various advantages and disadvantages of freeze-drying. Let us look at a few important ones.

Disadvantages:

- Very expensive process.

- The cost of machine is too high (3 times more expensive than equipment used for other separation process)

- Long processing time that can sometimes take a few weeks

- High energy costs as these machines require high energy to operate (2 to 3 times more than other methods)

- Freeze-dried food is expensive to buy

- Care needs to be taken while storage, so as to not expose them to moisture as they absorb moisture easily and degrade

- Need airtight containers for storage

- Products are frail and can crumble easily

Advantages:

- Can be applied to materials that are heat sensitive as the operating temperature is very low.

- Heat sensitive substances like proteins, enzymes, blood plasma etc. can be freeze dried without damaging the substances

- Minimal damage is caused while freeze-drying and minimal loss of activity in heat sensitive substances

- Rehydration is fast and complete and is very easy

- Maintains the quality of the food with the nutritional value and flavours intact.

- Foods that are freeze-dried do not need to be stored in refrigerator

- Reduces the weight of the substances making it easier for transport.

- Does not reduce volume of the substance, instead pores are left while freeze-drying in places where there were ice crystals (porous, crumbly structure)

- The products are of less weight and hence easy to store and transport.

Freeze Dried vs. Dehydrated

Difference between Freeze-drying and Dehydration:

Freeze-drying and dehydration process are totally two different processes and the resulting products have a huge difference in various aspects. Let us have a look at the most important factors that differentiate them both.

| Freeze-Drying process | Dehydration process |

|---|---|

The products look natural and there are no damages caused by heating the product as the complete process maintains frozen temperatures throughout the drying process | The products do not look natural and there are high chances for damages in tissues and in sensitive components |

There is no or minimal shrinkage | Causes undesirable shrinkage |

There is no issue with increased concentration and the products have similar concentration as the original substance. Rehydration is very easy | Increases concentration of the components and sometimes these form a thick skin at the top that slows down drying and later slows down rehydration too |

Reconstitution is instant as adding warm water can reinstate the food to the original form and texture | Many food need to be cooked for reconstitution, and hence it is a waste of time and energy. The food lose nutrition too |

The nutritional value is maintained | Reduces nutrition value while drying |

Texture is the same when rehydrated | Texture is altered drastically |

Facts about freeze-drying:

- The ancient Peruvian Incas of the Andean civilisations used the freeze drying process to preserve potatoes and these were called Chuno. They stored their potatoes and other food crops in the high mountain above Machu Picchu. At the higher altitudes, the food froze and water inside it vapourised slowly under low air pressure.

- A Swedish company has developed a procedure to freeze dry bodies (ecological burial), a process that dries the dead body with liquid nitrogen.

Comments

Dahlia Ambrose (author) from United Kingdom on March 22, 2016:

Hello FlourishAnyway,

Thank you for reading and sharing your thoughts and ideas. I am glad that you liked this hub :-)

Dahlia Ambrose (author) from United Kingdom on March 22, 2016:

Hello torrilynn,

Thank you for stopping by and the votes. I am glad that you found this hub interesting. :-)

Dahlia Ambrose (author) from United Kingdom on January 05, 2016:

Hello aviannovice, so sorry for the late response. I am so pleased that you found this hub informative. It indeed is quite expensive, must be because of the equipments used that are expensive and also you have the benefit of preserving them for a long time. Thank you for sharing your ideas and experiences. Have a great 2016! :)

Dahlia Ambrose (author) from United Kingdom on January 05, 2016:

Hello Joan King, thank you for passing by. Yes, freeze drying is an industrial process and requires expensive equipments. I see that it preserves the colours and shapes of the flowers too. Have you tried heat drying? How do the flowers or leaves turn out? I haven't tried either, so not able to compare the pros and cons of both. Thank you so much for sharing your opinion. Have an awesome 2016! :)

Dahlia Ambrose (author) from United Kingdom on January 05, 2016:

Hello mehak kush, thank you so much for stopping by and dropping a line. I am glad that you found this helpful!

mehak kush on December 24, 2015:

It is very helpful article as it contains all required information about lyophilisation.

Joan King on September 21, 2015:

Sounds complicated so I guess I will stick to heat drying. Great information.

Deb Hirt from Stillwater, OK on May 29, 2015:

This was certainly very informative, as I had a lot of questions answered while reading this material. Now I know why the process adds more expense to the original cost!

Elaina Baker from USA on May 13, 2015:

This was comprehensive and well-researched. It seems like one good way to deal with surplus vegetables during the summer.

torrilynn on May 11, 2015:

thanks for this hub. it was very unique and interesting. also, i liked the facts that you included at the end. voted up.

Dahlia Ambrose (author) from United Kingdom on May 11, 2015:

Hi Suzie,

Thank you for reading and for your valuable feedback. I am glad that you found this interesting. Have a lovely week ahead :-)

Dahlia Ambrose (author) from United Kingdom on May 11, 2015:

Hi Deergha,

Thank you for stopping by. I am glad that you found this useful and thank you for the votes.

I am fine thank you and hope you are doing well too. Hope you had a lovely weekend. Have a great week ahead. Hugs :-)

Dahlia

Dahlia Ambrose (author) from United Kingdom on May 11, 2015:

Hi Bill, thank you for your support and feedback. Have a lovely week ahead :-)

Suzanne Ridgeway from Dublin, Ireland on May 10, 2015:

Hi livingsta,

What wonderful info on freeze drying and its uses - love it! As always your attention to detail is excellent, many thanks for a well written informative piece. Up, useful and interesting!

deergha from ...... a place beyond now and beyond here !!! on May 09, 2015:

Hi dear Friend,

It's a very well researched and time relevant hub here. Your presentation is very engaging and informative with detailed descriptions. Never was so much actually aware about freeze drying process. Thanks for this wonderful share.

Shared and votes up useful.

Hope you are doing great. Happy mothers day, friend

Enjoy your day ahead....

warm hugs your way

Deergha

Bill Holland from Olympia, WA on May 09, 2015:

Nice research, good explanation, very interesting.